Wij gebruiken cookies om uw ervaring beter te maken. Om te voldoen aan de cookie wetgeving, vragen we uw toestemming om de cookies te plaatsen. Meer informatie.

ICPDAS MP-8343

Standard PAC controller for machine automation with EzProg-I package

EzProg-I development suite is a software package for the windows CE 5.0/6.0 platform consisting of numerous utilities and libraries which assist the system developer in developing a control system on the PAC in a short period of time. EzProg-I enable system engineers to increase efficiency of operations by simplifying and reducing the time required in implementing a control solutions. The development suite has the following advantages for the user:

EzProg-I enable system engineers to increase efficiency of operations by simplifying and reducing the time required in implementing control solutions. The development suite has the following advantages for the user:

● Simple and visually appealing I/O monitoring HMI can be created by dragging and dropping of ActiveX objects, without the need of any programming.

● PLC like programming by providing multitasking structure

● Extensive motion control libraries and utilities for writing motion control macros which make it easy to write application programs for ICP DAS' s multi-axis motion control cards.

The EzProg-I development suite comprises:

● Human machine interface (HMI) objects (ActiveX)

● Configuration tools and utilities

● I/O libraries

● Motion control tools and libraries

● Librarier for serial and network communications

Powerful and Easy to Use

EzProg-I is a total solution for system configuration, logic programming and HMI design for manufacturers or control system designers. Engineers who are familiar with programming PLC systems can easily migrate to EzProg-I and become acquainted with the software solution. EzProg-I makes it much easier for customers to integrate PLC and IT technologies.

The EzProg-I package contains many kinds of development tools and libraries such as EzConfig, EzGo, EzMake, EzHMI, EzLIB and EzCore. Based on these development resources, customers can directly configure and test the PAC's I/O channels and motion control modules without any additional programming effort. Moreover, EzProg-I simplifies the I/O instructions and provides I/O mapping table equivalent to the PLC system. It assists the system developer to design, construct and test its control system.

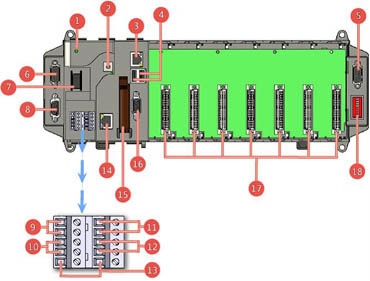

Overview Item Description

1. Power LED Indicator

2. Rotary Switch

3. Ethernet Port 1

4. USB 2.0 Ports

5. COM Port 5 (RS-232)

6. COM Port 4 (RS-232/RS-485)

7. Power Switch

8. COM Port 2 (RS-232)

9. Power and Ground

10. COM Port 3 (RS-485)

11. Redundant Power and Ground

12. Relay Output R.COM and R.NO

13. Frame Ground

14. Ethernet Port 2

15. CF (Compact Flash) Card Slot

16. VGA Port

17. Slot 1 ~ Slot 7

18. DIP Switch

| Operating System | Microsoft Windows CE 6.0 |

| CPU | AMD LX 800 processor | ||

| System Memory | 512 MB DDR SDRAM | ||

| Dual Battery Backup SRAM | 512 kB (for 5 years data retention) | ||

| Flash | 4 GB as IDE Master Speed | ||

| EEPROM |

|

||

| CF Card | Minimum 1 GB (support up to 32 GB) | ||

| 64-bit Hardware Serial Number | Yes | ||

| Dual Watchdog Timers | Yes | ||

| Rotary Switch | Yes (0 ~ 9) | ||

| DIP Switch | Yes (8 bits) |

| VGA | Yes (resolution: 1600x1200, 1024x768, 800x600, 640 x480) | ||||

| Ethernet |

|

||||

| USB 2.0 | 2 | ||||

| COM1 | Internal communication with I-87K modules in slots | ||||

| COM2 | RS-232 (RxD, TxD and GND); non-isolated | ||||

| COM3 |

|

||||

| COM4 | RS-232/RS-485 (RxD, TxD, CTS, RTS and GND for RS-232, Data+ and Data- for RS-485); non-isolated | ||||

| COM5 | RS-232 (RxD, TxD, CTS, RTS, DSR, DTR, CD, RI and GND); non-isolated |

| Slot Number | 3 slots |

| Support Modules Type | High profile modules only |

| Input Range | 10 ~ 30 VDC |

| Isolation | 1 kV |

| Redundant Power Inputs | Yes, with one power relay (1 A @ 24 VDC) for alarm |

| Capacity | 1.8A, 5V supply to CPU and backplane, 5.2A, 5V supply to I/O expansion slots, total 35 W |

| Consumption | 14.4 W (0.6 A @ 24 VDC) |

| Dimensions (w x l x h) | 231 x 132 x 125 mm |

| Installation | DIN-Rail or Wall Mounting |

| Operating Temperature | -25 °C ~ +75 °C |

| Storage Temperature | -30 °C ~ +85 °C |

| Humidity | 5 ~ 90% RH, non-condensing |